Unidirectional carbon fiber fabric

Carbon fiber strip

High strength carbon fiber

Carbon fiber is a new and advanced synthetic material, which was initially applied in aerospace for its high strength to weight ratio. Now it’s been widely used in many industries, e.g. construction, wind energy, storage tank and automotive etc. Our company always sources the high quality T700 grade carbon fiber to weave the fabric for our customers. The strength can reach 4900MPa, while with 230GPa elastic modulus.

Green material basalt fiber

Basalt fiber is made from a single material, crushed basalt, from a carefully chosen quarry source which is formed by the rapid cooling of lava and unlike other materials such as glass fiber, essentially no materials are added. The basalt is simply washed and then melted. The basalt fiber is just made from the melted. The fibers typically have a filament diameter of between 9 and 13 μm. They also have a high elastic modulus, resulting in excellent specific tenacity—three times that of steel.

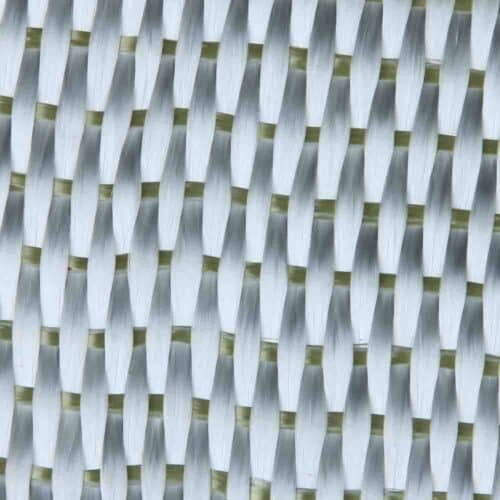

Glass fiber

Glass fiber is much cheaper compared with carbon fiber, while its strength is still 5x higher than steel. It can be used to produce woven textile, chopped strand mat, filament winding, knitted textile, geo-grid, profiles. Our company cooperates with reliable manufacturers, such as Jushi, Taishan to supply the best quality to our customers over the world.

Aramid fiber

Aramid fiber is well known for its bullet-proof and cut-proof properties. However, because of its good extendability and high modulus, it can absorb huge impact power through its own deformation. And it’s plastic failure compared with the brittle failure of CFRP. So it’s widely applied in aerospace, blasting protection facilities and pier strengthening. Aramid fiber also has outstanding shear strength among the advanced composite materials.

Carbon/aramid hybrid fabric

It’s the creature of carbon fiber and aramid fiber, so it has the properties of both of them. Stronger than aramid fiber and more ductile than carbon fiber. There’re many different colors and woven patterns available. It can be widely applied in automotive and sports. These equipments made from carbon/aramid have wonderful appearance and are very durable, light weight.