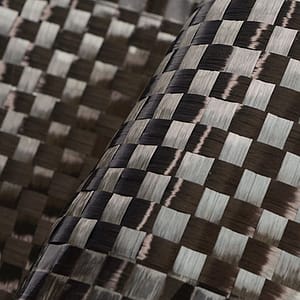

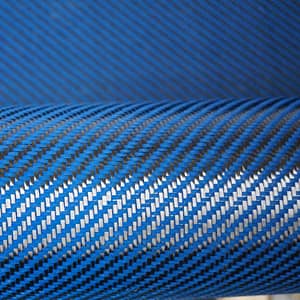

Carbon fiber mesh is a bidirectional woven mesh, with high strength and non-corrosion properties. The carbon fiber yarns are aligned in 0˚ and 90˚ direction, so that it has equivalent high strength in both directions. It should be used together with cementitious matrix to improve the mechanical properties of the structures. Besides, MaxTM CF mesh can efficiently reduce cracks on the substrates. Different mesh weight and mesh size can be customized as per customer’s requirement. We also supply mesh coated with epoxy, polyester, vinyl ester etc to meet different projects’ design. It’s a promising innovation.

Carbon Fiber Mesh Concrete Reinforcement: A Promising Innovation

Carbon fiber mesh concrete reinforcement (CFRP) is emerging as a promising alternative to traditional steel reinforcement in concrete structures. It offers several advantages, making it an attractive option for various applications.Here’s what you need to know about CFRP:

Composition and Properties:

- CFRP consists of a network of thin, high-strength carbon fibers embedded in a polymer matrix.

- Compared to steel, CFRP boasts:

- Lighter weight: Reduces overall weight of the structure, enhancing efficiency and potentially simplifying construction.

- Higher strength: Can withstand tensile stresses exceeding steel, enabling thinner elements or increased load capacity.

- Corrosion resistance: Immune to rust and degradation from harsh environments, extending the lifespan of structures.

- Low thermal expansion: Minimizes thermal stress and cracking, especially important in structures exposed to temperature fluctuations.

- Radio transparency: Valuable in applications like MRI scanners or radar domes.

Applications

- Increase load capacity

- Strengthening structures for different use

- Seismic retrofit

- Increase flexural strength and shear strength

- Structural reinforcement

- Concrete repairs

- Seismic retrofitting

- New construction: CFRP can be used in beams, columns, slabs, and walls, offering design flexibility and potential cost savings.

- Retrofit and repair: Strengthens existing structures without adding significant weight, ideal for historical buildings or seismic upgrades.

- External strengthening: Applies to concrete surfaces for targeted reinforcement, addressing specific load requirements.

- Thin-walled structures: Enables thinner elements with high strength, valuable for architectural aesthetics or weight-sensitive applications.

Applications Fields

- Tunnel strengthening

- Bridge strengthening

- dock strengthening

- column strengthening

- Wall strengthening and stop bowing

How to Apply?

Surface Preparation

It’s much easier to apply carbon fiber mesh as FRCM than traditional FRP wrap strengthening. FRCM has much lower requirement on the structure surface. The surface should be sound, dust free and moistened to saturation without residual water.

Apply 1st Layer of Cementitious MatrixIt can be done by spray or manually with spatula. The thickness should be 3-5mm.

Embed the Carbon Fiber MeshEmbed the mesh in the Cementitious Matrix.

Apply 2nd Layer of Cementitious MatrixThe 2nd layer of matrix is approximately 3mm thickness to ensure the completely cover and protect the carbon mesh.

CautionThe environment temperature may affect the workability of the cementitious matrix, high temperature reduces the workability and vice verse.