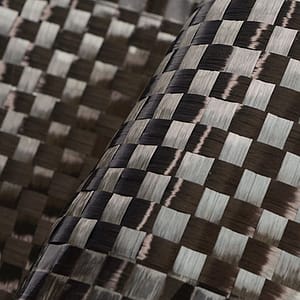

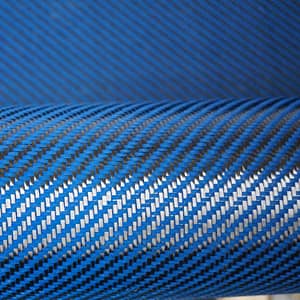

Carbon fiber tape is simply narrow strips of woven carbon fabric, with width from 5cm to 10cm. Ideal for localized reinforcement of carbon fiber fabrications, sleeve winding, lap joining, and repairs of cracks on graphite surfaces without the need to cut down large pieces of fabric. Plain weave carbon fiber tape also has several potential applications in pipe repair, depending on the specific type of pipe, damage, and desired outcome. Here are some key points:

Features

- Plain weave for uniform strength in both directions.

- Easily and quickly wet out

- High strength and light weight

- High strength and stiffness: Carbon fiber boasts exceptional strength and stiffness compared to traditional repair materials like steel or fiberglass. This allows for significant reinforcement with minimal added weight, especially crucial for large diameter pipes.

- Corrosion resistance: Unlike steel, carbon fiber is highly resistant to corrosion, making it suitable for repairs in environments prone to moisture, chemicals, or salt water.

- Good fatigue resistance: Pipes experience repeated stress due to pressure and flow variations. Carbon fiber’s fatigue resistance ensures the repair maintains its integrity over time.

- Flexibility: While not as drapeable as other weaves, plain weave offers some flexibility, allowing for application on pipes with slight bends or curves.

Applications

- Structural strengthening

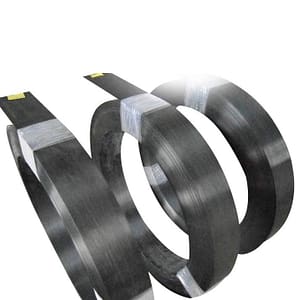

- Oil pipe or gas pipe repair

- Moulding

- Composite parts repair

- Reinforcement for minor cracks and leaks: Carbon fiber tape can be applied over small cracks or leaks to strengthen the pipe and prevent further damage. This is often combined with epoxy resin for a secure bond.

- Localized reinforcement for stress points: Areas experiencing high stress, such as pipe connections or bends, can benefit from localized reinforcement with carbon fiber tape. This adds stiffness and helps distribute stress more evenly.

- Repairing larger defects: In some cases, carbon fiber can be used for structural repairs of larger defects, such as punctures or breaks. However, this typically requires expertise and specific repair systems designed for the pipe material and pressure rating.

- Corrosion protection: The corrosion resistance of carbon fiber makes it suitable for wrapping pipes exposed to corrosive environments, providing an additional barrier to protect the underlying material.

Limitations

- Cost: Carbon fiber is a high-performance material, and its cost can be significantly higher than traditional repair materials.

- Installation expertise: Applying carbon fiber effectively often requires specialized training and knowledge of proper surface preparation, resin selection, and application techniques.

- Not suitable for all pipe materials: Depending on the specific pipe material and pressure rating, carbon fiber repairs might not be suitable or require additional considerations.

Any question or need more information?