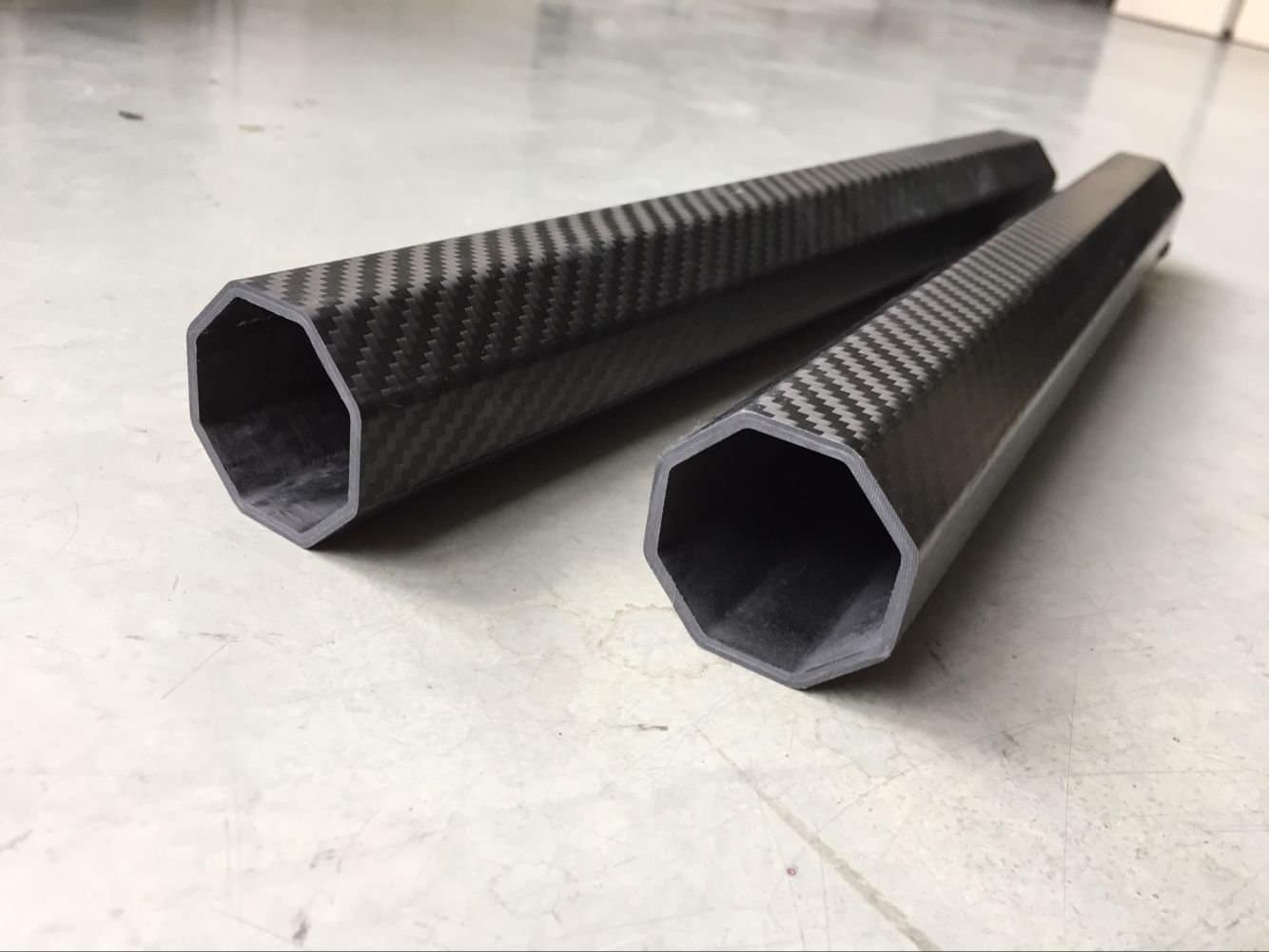

Carbon Fiber Profile

Advanced material with high strength and low weight

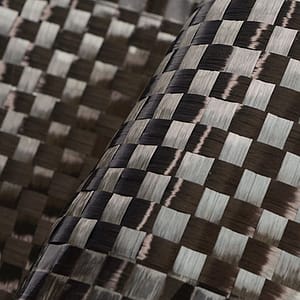

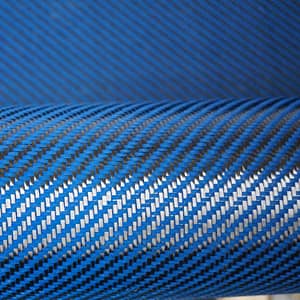

The product is made from aerospace grade carbon fiber and certain type of resin through wind or pultrusion. The resin could be epoxy base, polyester base and vinyl ester base as per specific project requirement. It’s an alternative to conventional materials, such as aluminum, steel, etc. Thanks to its high strength-weight ratio, it can provide ultra high strength and stiffness while obviously cut off the total weight, which can save energy consumption ideally. What’s more, there’s also high modulus carbon fiber, which behaves low elongation under high stress.

Carbon Fibre Technology

-

- Pultrusion. It involves pulling carbon fibers through a thermoset resin bath and then through a heated die. This process aligns the carbon fibers axially and wets them with resin, creating a strong and lightweight product. Pultrusion is typically used for the production of long, straight parts such as rod, laminate, hollow profiles and other special shape.

-

- Prepreg lay-up. It is cured under heat and pressure. Parts made from prepreg are strong and lightweight with higher stiffness and strength and are well suited for use in a variety of high-end applications. Prepreg lay-up is normally used for the production of flat parts such as panels or sheets, or parts with cylindrical curvature because prepreg material will not drape well over compound curvatures.

Any question or need more information?