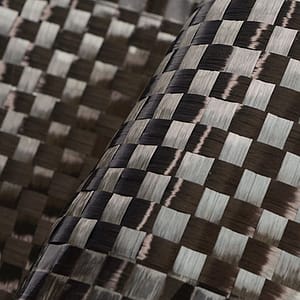

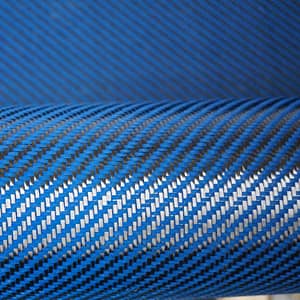

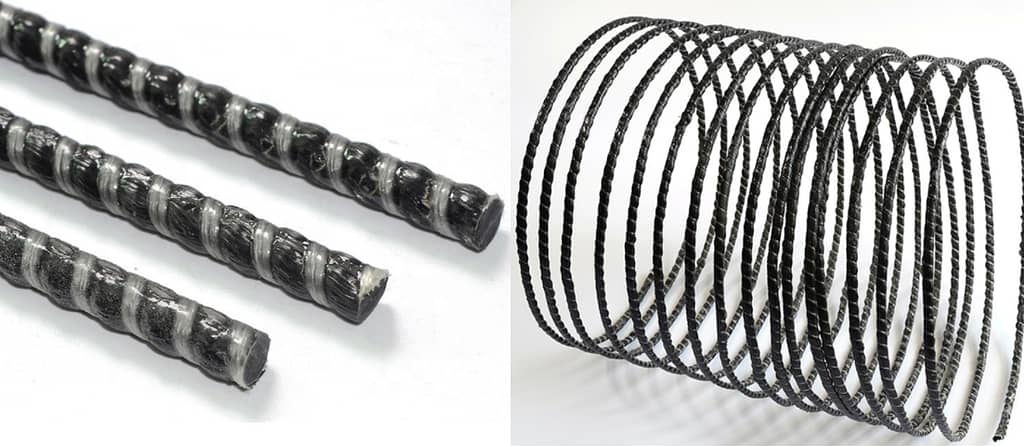

What is carbon fiber rebar?

Carbon fiber rebar is a kind of new advanced material, widely applied in structural strengthening, structural reinforcement, concrete repair, underground tunnel, highways, bridge, airport, dock, station, water projects, etc. Because of its anti-corrosion, it can be applied in sewage disposal facilities, chemical factory, electrolysis bath, manhole cover, marine facilities. It can be the solution to many existing projects problems, not like corrosive steel rebar, it brings the new opportunity for construction development.

Advantages

- high strength, 5x stronger than steel rebar, meanwhile with good anti-fatigue property.

- light weight

- anti-corrosive, no matter alkali or acid, the fiberglass rebar can retain its mechanical properties in harsh environment.

- low thermal and electricity conductivity.

- Non-magnetic.

- Easy handling. The carbon fiber rebar can be customized for different diameter and length as per project requirement. It can be tied with non-metal strap.

- Low impact on aesthetic

- A good alternative of steel rebar in the long run, considering the maintenance cost.

Concrete is the most common and tremendously consumed materials in construction industry. It has very excellent compressive strength, but unfortunately too weak in tensile strength. To overcome this weakness, we can add high strength steel rebar as the frame in structures. However, steel rebar also has its own fault, prone to corrode, sensitive to invasive chemicals. When corrosion and rust happens on the steel bar, it will expand in volume thus the internal pressure in around concrete will increase apparently, leading to more serious cracks in the structure. After numerous experiments and live projects, carbon fiber rebar is proven effective in structural strengthening and strength supplement, hence introduced to replace the steel rebar serving in harsh circumstances.

| Diameter | Cross Section(mm2) | Ultimate Tensile Force(KN) | Ultimate Tensile Strength(MPa) | Ultimate Shear Force(KN) | Ultimate Shear Strength(MPa) |

| ∅8 | 50 | 120.63 | 2412 | 27.38 | 273 |

| ∅10 | 73 | 217 | 2975 | 54 | 370 |

| ∅12 | 103 | 251 | 2445 | 64 | 313 |

Any question or need more information?