Basalt Fiber Rebar

Model: MAX-BFR

Introduction

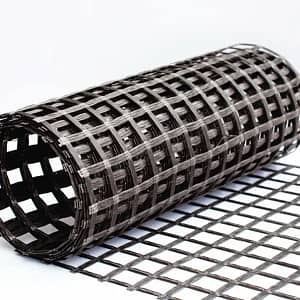

A Sustainable Alternative to Steel. Basalt fiber rebar is widely used in road construction, structural strengthening, structural reinforcement and concrete repair due to its superior performance over traditional steel bars. It is a sustainable, corrosion resistant, and lightweight material that is used to reinforce concrete and reduce the time and cost of construction. Its corrosion resistance makes it an ideal choice for areas subject to vehicular traffic or harsh environmental conditions.

Basalt fiber rebar is easy to apply and comes in various sizes to suit different applications. Before installation, one should ensure there is enough space for the rebar to be fitted and check for any sharp objects which can cause damage to the material. During installation, it is important to secure the bars properly and evenly to ensure they are well-anchored.

Mechanical Properties

| direction | CTE. x 10 -6/℃ | ||||

| steel | fiberglass | Basalt fiber | Carbon fiber | Aramid fiber | |

| longitudinal | 11.7 | 3.3-5.6 | 9-12 | (-4.0)-0 | (-3.3)-(-1.1) |

| transverse | 11.7 | 11.7-12.8 | 21-22 | 41-58 | 33.3-44.4 |

Properties of Different Rebars

| Item | Basalt rebar | Steel rebar | Copper rebar |

|---|---|---|---|

| Tensile strength(MPa) | ≥1000 | ≥500 | ≥430 |

| Yield strength(MPa) | ≥600 | ≥300 | ≥340 |

| Elastic modulus(GPa) | ≥50 | ≥200 | ≥110 |

| Density(g/cm3) | 1.9-2.1 | 7.9 | 8.9 |

Applications for underground projects

For the construction of underground parking, underground tunnel, underground station, underground stores, which have stricter requirement on strength than normal projects. Basalt fiber rebar is the best alternative because of its strength and modulus. Meanwhile, basalt fiber rebar is also widely applied in tunnel reinforcement and underground construction of oil storage.

Applications for anti-corrosive projects

Because basalt fiber rebar is resistant to chemical corrosion, it is good alternative to be applied in bridge, highways, ports, swimming pools, chemical factories, sewage disposal plants, nuclear power plants, chemical storage tank. Basalt fiber rebar won’t corrode when it comes to nitrate which is widely applied on the road to speed up the ice’s melting in winter. Basalt fiber can save the maintenance cost greatly.

- New construction: Used in beams, columns, slabs, and walls, offering design flexibility and potential cost savings.

- Retrofit and repair: Strengthens existing structures without adding significant weight, ideal for historical buildings or seismic upgrades.

- External strengthening: Applies to concrete surfaces for targeted reinforcement, addressing specific load requirements.

- Thin-walled structures: Enables thinner elements with high strength, valuable for architectural aesthetics or weight-sensitive applications.

Cost comparison

Basalt fiber rebar is more expensive than steel bars, but in the long run, basalt fiber rebar is a better alternative in consideration of its low maintenance cost and light weight and outstanding mechanical properties. In conclusion, basalt fiber rebar is an excellent choice for road construction projects due to its superior performance compared to traditional steel bars. With proper application and installation, basalt fiber rebar can help ensure the construction lasts longer and works better.

Projects

Any question or need more information?