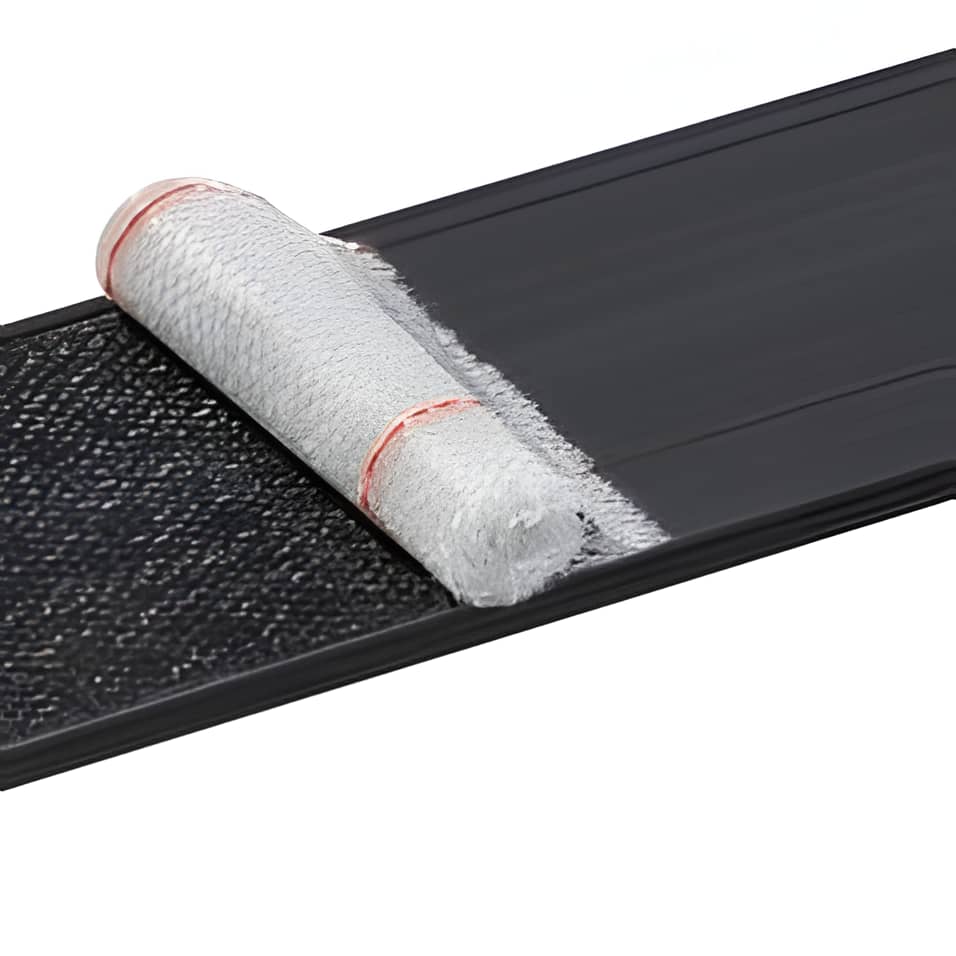

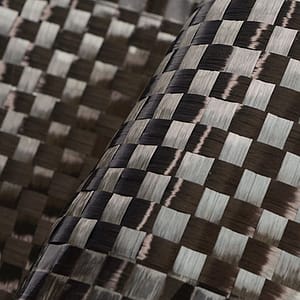

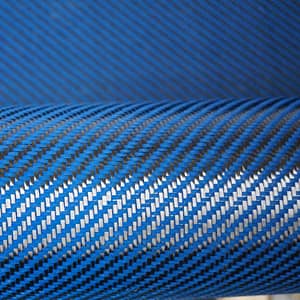

Carbon fiber plate, also called carbon fiber strip or laminate, is produced from PAN-based (polyacrylonitrile) carbon fiber and compatible resin, such as epoxy, polyester, vinylester. Carbon fiber has at least 10 times tensile strength than the steel with very low density. It’s acid resistant, alkali resistant, non-corrosion, fatigue resistant. The carbon fiber plate can be directly bonded to the structure after standard preparation of the structure surface to provide additional strength to the structural elements, no matter concrete, masonry or timber. The adhesive, also called putty, is a two part resin system, 100% solid state. Compared to the normal strips on the market, this kind of strips will provide higher bonding strength with the substrate surface because of the increased interactive area. Before being applied, the peel ply should be peeled off, in this way, no extra cleaning with acetone should be done to the strip surface, which also saves much project time and keeps workers healthy from harm, because acetone is harmful when inhausted. It’s widely used in structural strengthening, structural reinforcement, concrete repairs and seismic retrofitting.

Strengthening Projects

- Increase the live load capacity

- Increase the flexural strength

- Increase the shear strength

- Extend the service life of the building and give gauranteed safety

- Fix the problems resulting from design and construction defects

- Reinforcing the slabs for new openings

- Restore the strength of the structures damaged by earthquake, fire or other disasters

- stop wall bowing

Features

- High strength

- Low weight

- Acid resistant

- Alkali resistant

- Non-corrosive reinforcement system

- Fatigue resistant

- Low aesthetic impact

- Low maintenance cost

- Low labour cost

- Easy application and operations

- Save transporting cost

- Shorter downtime

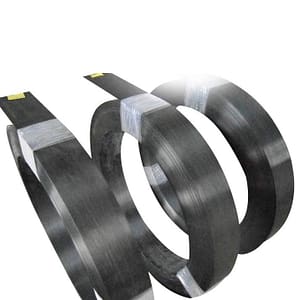

DIMENSION

-

1mm to 3mm Thickness

10mm to 150mm Width

50m or 100m for each package roll

Any question or need more information?