Carbon Fiber Rod (Bar)

What is pultrusion?

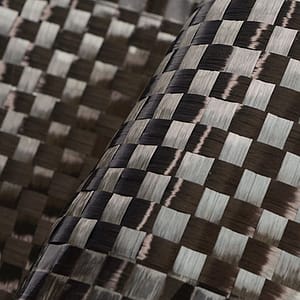

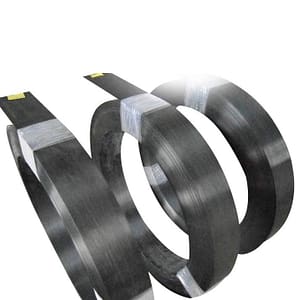

The carbon fibers are pulled from rolls through a heated die while simultaneously being saturated with resin. The shape of the die determines the shape of the finished profile. The resin cures as it’s being pulled through the heated die forming a rigid profile with precise dimensions. Since the process continuously pulls fiber and resin through the die, the maximum length is only limited by how long the fiber rolls are and how much space is available for the finished part. The fiber volume fraction is approximately 75%, which makes our rods stronger and stiffer than other comparable ones. We have wide range of carbon fiber rods with different diameters, from 1mm to 20mm, and with customized rod length.

Advantages of Carbon Fiber Bar

- Superior mechanical properties, such as strength, modulus

- Straight in the direction

- High carbon fiber volume rate

- Smooth surface finish

- Light weight

- High stiffness

Applications

- Aerospace

- Plane modeling

- Medical equipment

- Chemical facilities

- Structural strengthening, embed the bars in the slots prepared through cutting in advance, which is called near surface mounted, NSM in short

- Structural reinforcement

- Concrete repairs

- Seismic retrofitting

Handling

The CFRP bar can be easily tailed to your desired length with easy band saw cutting. However, do wear necessary mask and gloves to protect yourself from the generated dust during cutting and sanding .

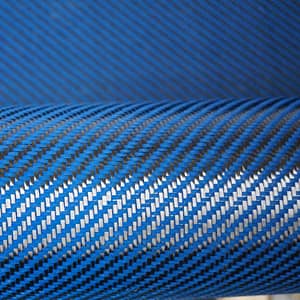

- Material: Carbon fiber

- Finished: Smooth

- Diameter: 4mm to 20mm

- Length: 1meter

Any question or need more information?