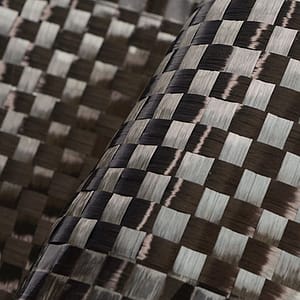

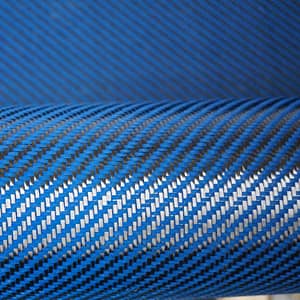

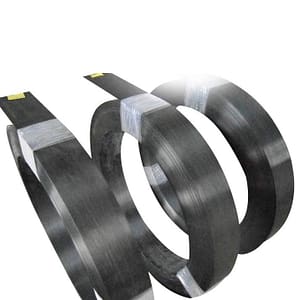

MaxTM Pultruded Profiles are pre-cured, thick-ply carbon fiber laminates for ideal structural reinforcement applications. Available in a variety of thicknesses and complex shapes, our pultrusion products deliver optimized properties with high fiber volumes, nearly zero void content, and locked-in filament alignment.

Carbon fiber tows are fed into our proprietary impregnation and curing process which creates smooth carbon fiber laminates resulting in efficient laydown when building thickness. The specific fiber alignment achieved with pultrusion delivers consistently better overall properties in laminates than any other composite manufacturing process. Depending on the end application, these pultruded profiles are typically produced with a thermoset epoxy or vinyl ester resin in a proprietary low-cost, high-throughput process.

Pultruded profiles are production-ready carbon composites for infrastructure applications, deep sea exploration, wind energy, and other applications benefiting from the unique properties of pultruded carbon fiber parts.

Showcase

Any question or need more information?