What is externally bonded CFRP plate?

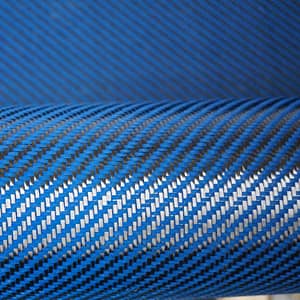

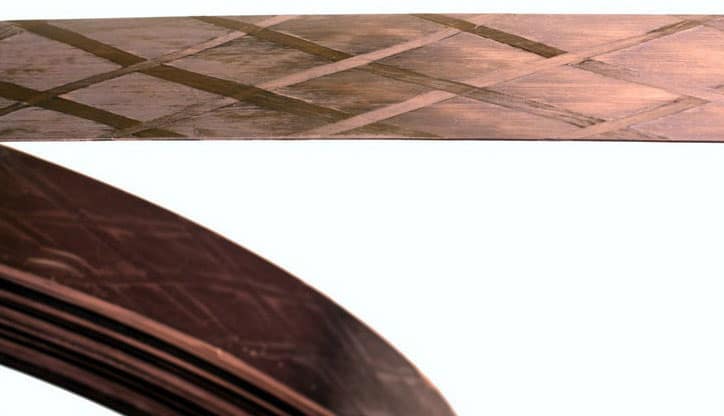

Carbon fiber plate, also called carbon fiber strip or laminate is pultruded from matrix of carbon fiber and epoxy resin through die with specific inner shape. It has at least 5 times tensile strength than the steel, whilst it is of such light weight. It is acid resistant, alkali resistant, non-corrosion, fatigue resistant, age resistant. It’s used in structural strengthening, structural reinforcement, concrete repairs and seismic retrofitting.The carbon fiber plate can be directly bonded to the structure after preparation of the structure surface to provide additional strength to the structural elements, no matter concrete, masonry or timber. The adhesive, also called putty, is two part resin system, 100% solid state. The CFRP plate is much easier to be applied than CFRP wrap, since you don’t have to worry about if the workers have saturated the CFRP wrap correctly, which is very crutial for the final strengthening result, succeed or fail. It has been consistently produced at same fiber and resin ratio. There’re 2 types of plate available, with or without peel ply coated. The carbon fiber plate without peel ply should be carefully cleaned to remove the dust and other particles to ensure the final bonding quality. In the other hand, the peel ply by which the plate is coated should be peel off before applying the plate. The plate surface will be clean and rough enough for the bonding process.The laminate thickness may vary from 1mm to 5mm thickness, width may vary from 10mm to 120mm. Compared to steel plate for the same strengthening and reinforcement purpose, the carbon fibre strip is way thinner, so you don’t have to worry about the strip cross each other during the bonding process. One more note is that necessary cover and coating process should be taken to prevent the CFRP strip and resin from direct sunlight, which may change their chemical composition, leading to the declined mechanical properties.

How to bond the CFRP plate?

Direct Bonding

- Remove the aged and loose concrete from the substrate

- Use high pressure air blower to remove the dust, grease, laitance and particles

- Deal with the corroded steel rebar and water leakage if any

- Repair the substrate inlcuding fillling the holes to ensure sound and even surface

- Paste the putty onto the strip surface with proper spatulas

- Bond the strip onto the prepared substrate surface

- Press the strip to remove extra putty and air with rubber roller

- Apply protective and decorative coating

Near Surface Mount(NSM)

- Remove the aged and loose concrete from substrate

- Cut the designed grooves with suitable saw-blade cutter

- Use high pressure air blower to remove the dust, grease, laitance and particles

- Deal with the corroded steel rebar and water leakage if any

- Repair the substrate inlcuding filling the holes to ensure sound and even surface

- Paste the putty onto the strip surface with proper spatulas

- Bond the strip onto the prepared substrate surface

- Press the strip to remove extra putty and air with rubber roller

- Apply motor to cover the strips

Post-tensioned Installation

It is explained in detail in the video below.

What is post-tensioned Installation?

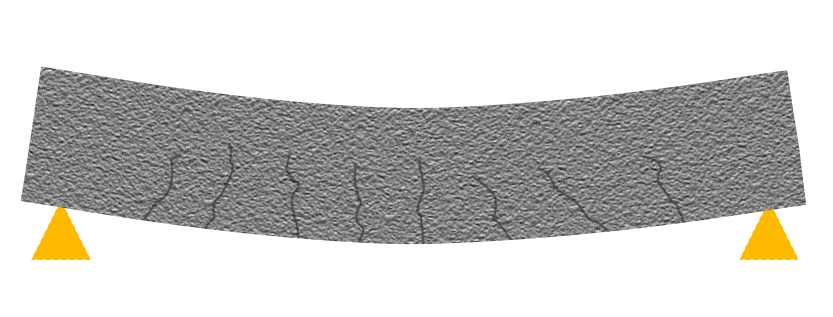

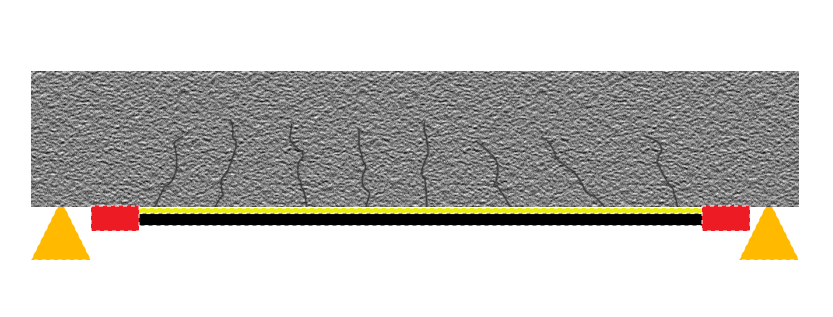

Post-tensioned CFRP plate is a new advanced strengthening technology in the construction industry. It can fully utilize the high strength of the CFRP plate to transfer the external stress normally introduced by the hydraulic jack to the RC structures which is suffering flexural bending, either positive movement or negative movement. The externally added stress can counteract the overloaded capacity. Externally bonded CFRP without tension will only function when more serious deforms happen, which is called passive strengthening. While externally bonded CFRP with tension will function immediately when it’s been installed, furthermore the cracks and existing deforms can be fixed and mitigated, which is unachievable by EB CFRP without tension. The PT system consists of a dead end and a live end. The dead end works to fix one of the ends of CFRP strip. The live end works to fix the other end of the CFRP strip after certain stress is deployed to the strip by hydraulic jack. The PT system is very effective in improving the load carrying capacity and protecting the structures from earthquake damages.

Before PT Strengthening

After PT Strengthening

WHERE TO APPLY?

- Increase the load capacity

- Increase the flexural strength

- Increase the shear strength

- Extend the service life of the building

- Fix the problems because of design defects and construction mistakes

- Reinforcing the slabs for new openings

- Restore the strength of the structures damaged by earthquake, fire or other disaster

ADVANTAGES

- High strength

- High modulus

- Low weight

- Acid resistant

- Alkali resistant

- Non-corrosive reinforcement system

- Fatigue resistant

- Low aesthetic impact

PACKAGING

- 100mm width plus 1.2mm thickness, rolled in 100m length

- 50mm width plus 1.2mm thickness, rolled in 100m length

- 100mm width plus 1.4mm thickness, rolled in 100m length

- 50mm width plus 1.4mm thickness, rolled in 100m length

The highway girders are strengthened with CFRP plate to increase load capacity and flexural strength and the columns are wrapped with CFRP fabric to increase axial load capacity and ductility and compressive strength.

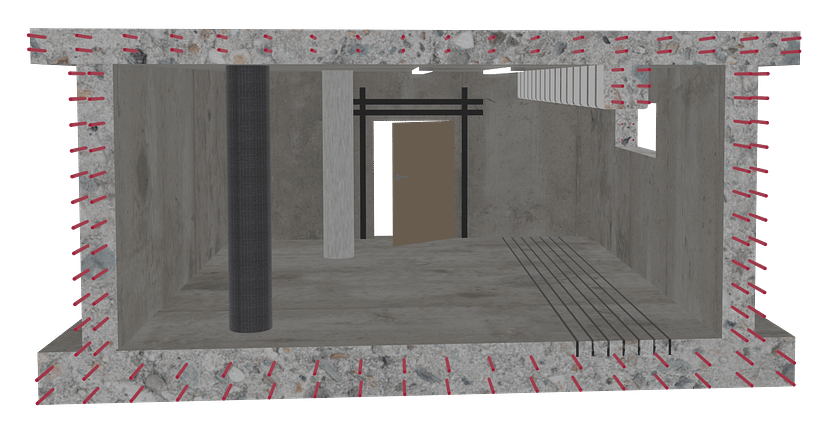

The CFRP plate and wrap can be widely applied on the members of RC structures in different ways, like NSM and structural bonding.

CFRP plate post-tensioned bonding

Carbon Fiber Plate with Peel Ply

Anchorable Carbon Fiber Plate

Any question or need more information?