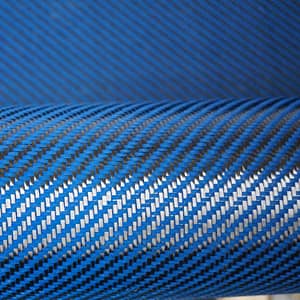

spread tow carbon fiber fabric

Lighter. Spread tow carbon fiber fabrics are woven from fiber tows that are spread into thin tapes. Tape area density is inversely proportional to spreading width. Whereas the lightest traditional carbon fiber fabrics weight 90 g/m2, spread tow fabrics can achieve densities as low as 40 g/m2.

Straighter fibers. Compared with traditional reinforcement fabrics, spread tow fabrics have practically straight carbon fibers. Straight fibers have a higher rigidity in tension than undulated fibers and result in a stiffer fabric. Since their buckling is not initiated, straight fibers also have a better resistance to compressive stress.

Higher fiber-to-matrix ratio. Since spread tow carbon fiber fabrics are extremely flat, they require less resin than traditional fabrics to be impregnated. This results in composites with a higher fiber-to-matrix volume ratio and overall better mechanical performances.

Because they have practically straight fibers and a woven structure, spread tow carbon fiber fabrics combine the stiffness of non-crimp laminates and the reduced delamination risks of woven fabrics.

Any question or need more information?