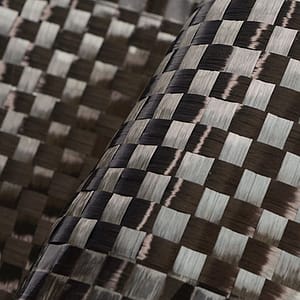

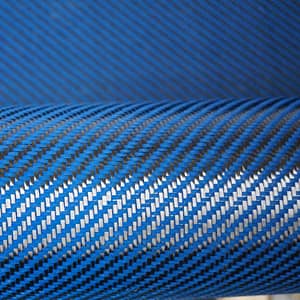

Stitched carbon fiber fabric is warp knitted unidirectional fabric. It’s flatter and the carbon fiber yarns are straighter compared with the woven carbon fiber fabric. Thus, the stitched carbon fiber fabric has better mechanical properties and won’t come apart when saturated with the resin by scratching. It’s widely used in structural strengthening, structural reinforcement, concrete repair, boat building, wind turbine blade and sports goods.

Stitched carbon fiber fabric, also known as non-crimp fabric (NCF), is a type of carbon fiber reinforcement made by stitching together individual tows (bundles) of carbon fibers. Unlike woven carbon fiber fabrics, where the fibers interlace over and under each other, the fibers in stitched fabrics are held together by stitches running parallel to the tows.

Advantages

- Reduced fiber crimp: Crimp, which occurs when fibers bend, can negatively impact the strength and stiffness of the composite material. Stitching minimizes fiber crimp, leading to improved mechanical properties.

- Even thickness & easy wet-out

- Tailored fiber orientation: Stitches can be oriented in specific directions to optimize the strength and stiffness of the fabric in different directions. This is particularly beneficial for complex shapes or applications where multi-directional loading is expected.

- Good flexibility and easy handling

- Drapeability: Stitched fabrics offer better drapability compared to woven fabrics, making them easier to conform to curved surfaces. This is important for applications like aircraft components or boat hulls.

- Lower cost: Stitching technology can be simpler and less expensive than weaving, potentially reducing the overall cost of the fabric.

Stitched carbon fiber fabrics are used in a variety of applications, including:

- Aerospace: Aircraft wings, fuselages, and other structural components.

- Automotive: Car bodies, wheels, and other performance parts.

- Sporting goods: Tennis rackets, golf clubs, and other equipment.

- Marine: Boat hulls, masts, and other components.

- Medical devices: Prosthetic limbs and other implants.

When choosing stitched carbon fiber fabric for a particular application, it is important to carefully consider the specific requirements and select a fabric with the appropriate properties and stitch pattern. Consulting with a materials engineer or composite specialist can help ensure you choose the right material for your needs.

Any question or need more information?