Introduction About Carbon Fiber Wrap

Properties and Usage

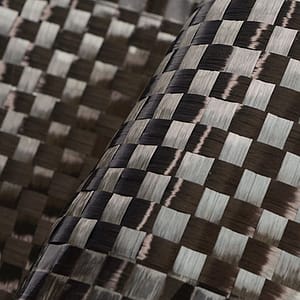

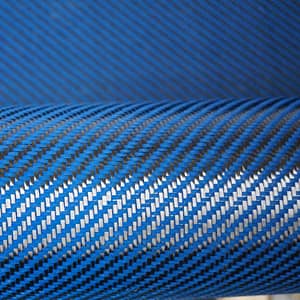

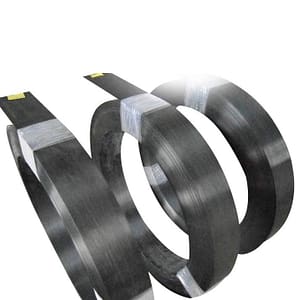

Unidirectional carbon fiber fabric is made from high strength carbon fiber. The tensile strength of dry fiber can be higher than 4900MPa, which is almost 10 times stronger than steel, whilst with only 1/5 weight of steel. It is widely used in structural strengthening, structural reinforcement, concrete repair, increasing load capacity of structures, seismic retrofit, increasing shear strength and flexural strength, extending structure’s service life and correcting design defects and construction mistakes.

Replacement of Traditional Materials for Structural Strengthening

Carbon fiber wrap functions as externally bonded reinforcement when adhered to the surface of a reinforced concrete member requiring strengthening, with its primary fibers oriented in a desired direction. Resin matrix not only aligns the fibers in the preferred direction but also acts as a load transfer medium between the structure and the fibers and protects the fibers from external damage and impact .And Carbon fiber reinforced polymers(CFRP) system for strengthening of concrete structures have emerged as an efficient and viable alternative of traditional strengthening techniques, such as replacement of structure members, RC jacketing, steel jacketing .

Standard Weight and Dimension

An CFRP system comprises of an externally bonded composite reinforcement layer that is designed to an appropriate thickness and size to provide a quick, simple and effective means for increasing the capacity of the structural element against failure. We have standard weight like 200GSM, 230GSM, 300GSM, 400GSM, 600GSM, standard width 50cm, standard roll length 50m and 100m. For special size and packing, we would be glad to customize for our customers.

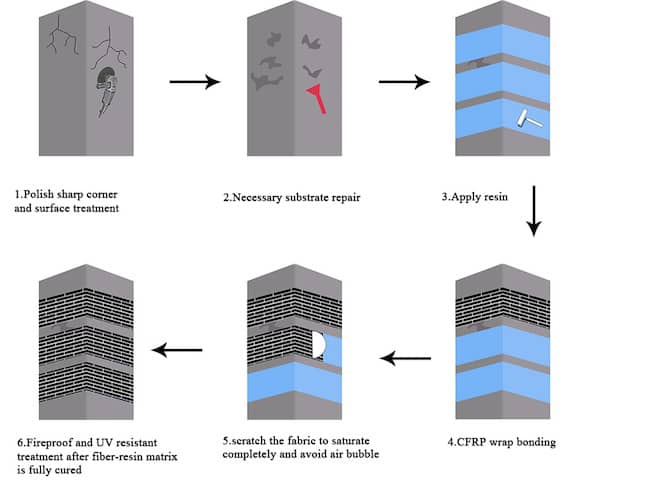

Cautions for Operation Process

To ensure proper bonding between the composites and concrete substrate, surface preparation is crucial. The concrete surface to be applied with CFRP should be free from dust, laitance, oil, grease, surface defects, corrosion products, fungal growth, cracks. Prior to CFRP application, all cracks wider than 0.3mm should be pressure injected with a low viscosity epoxy. Root cause of cracking should be addressed along with injection. All defective or damaged concrete surfaces must be repaired with approved repair materials. Causes of corrosion in reinforcement, if any, must be addressed and the corrosion related deterioration should be repaired prior to the application of CFRP system.

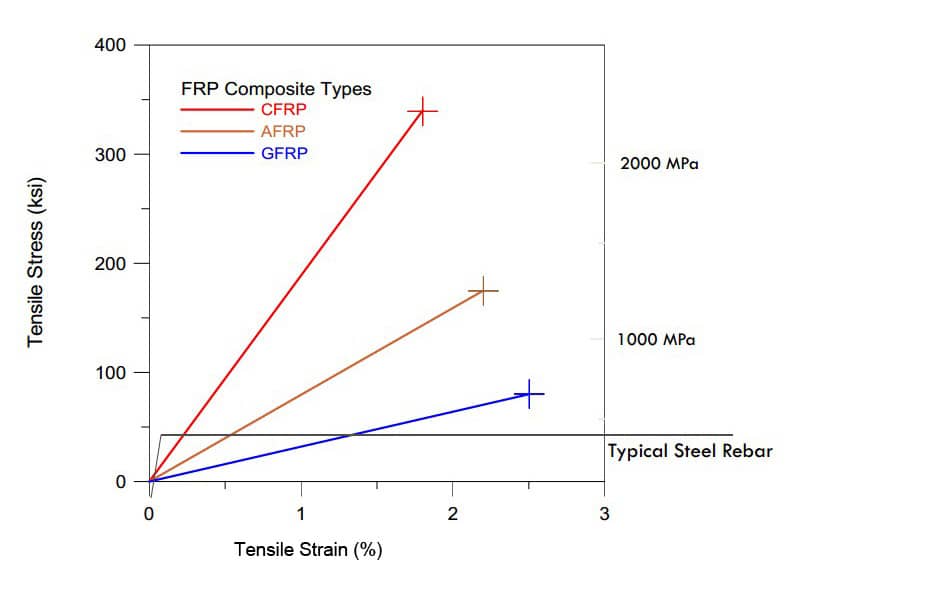

Comparison with Other FRP Materials

As shown in the graph below, CFRP has much higher elastic modulus than other composite materials, e.g. AFRP(aramid fiber reinforced polymers), GFRP(glass fiber reinforced polymers) and the new rising BFRP(basalt fiber reinforced polymers). So under high load or stress, debonding failure may happen. To avoid such failure, we may utilize fiber anchor and steel plate clamps. In this way, the advantage high strength and modulus of CFRP can be greatly developed.

Standard Models of CFRP Wrap

| Item Model | Areal Weight(g/m2) | Fabric Width(cm) | Roll Length(m) | Strength(MPa) | Modulus(GPa) | Elongation(%) |

|---|---|---|---|---|---|---|

| MAX-CT20T | 200 | 50 | 100 | 4900 | 230 | 2.1 |

| MAX-CT23T | 230 | 50 | 100 | 4900 | 230 | 2.1 |

| MAX-CT30T | 300 | 50 | 100 | 4900 | 230 | 2.1 |

| MAX-CT60T | 600 | 50 | 50 | 4900 | 230 | 2.1 |

| MAX-CT90T | 900 | 50 | 50 | 4900 | 230 | 2.1 |

Application Steps of Dry CFRP Wrap Laying Up

- Surface preparation, crack repair, leak stop, get rid of the loose concrete, make the substrate sound and even

- Apply primer on the substrate surface

- Apply putty if necessary to fill the voids in substrate

- Apply saturant on the substrate surface

- Wrap the structure surface with the tailored carbon fiber fabric

- Saturate the fabric by applying second coat of saturant along the fabric, ensure that there is no air bubble existing in the fiber-resin matrix

- FRP wrap application is completed, however, keep the structure from any impact during the following 24hrs and apply protective and decorative coating if required

Application Steps of Wet CFRP Wrap Laying Up

- Surface preparation, crack repair, leak stop, get rid of the loose concrete, make the substrate sound and even

- Apply primer on the substrate surface

- Apply putty if necessary to fill the voids in substrate

- Saturate the tailored carbon fiber fabric completely in the resin bath and squeeze out the extra resin

- Wrap the structure surface with the resin saturated carbon fiber fabric

- FRP wrap application is completed, however, keep the structure from any impact during the following 24hrs and apply protective and decorative coating if required

Advantages with CFRP Wrap for Structural Strengthening and Reinforcement

- Light weight, high strength, high elastic modulus, high strength-to-weight ratio

- Easy to handle, not require heavy equipment, labor cost savings

- Shorter construction period compared with other strengthening methods, which means less down time of the structure

- Little disturb to the running of the structures, such as bridge, factory

- Non corrosive, after the fiber-resin matrix is cured, it’s impervious, which protects the structures from moisture intrusion and further corrosion.

- Alkali resistance

- Good aging resistance

- Add insignificant weight to the existing structure, meanwhile, it significantly increases the load capacity of the structure.

- Low aesthetic impact

- No regular maintenance after being strengthening

- Can be applied with limited access where other traditional strengthening methods are impossible

- Well conforms to any structure surface thanks to its flexibility

- Waterproofing

Where is the carbon fiber applied for structural reinforcement?

- Structural damages by accidents, such as fire disaster, traffic crash or natural disaster like earthquake

- Remedy the construction faults due to design or construction mistakes

- Make the structure stronger to improve its earthquake resistant capability

- To conform to the updated construction standard

- Increase the structure’s load bearing capability for extra load such as heavy equipments

- Strength supplement due to new openings on slabs, walls

- Increase the column’s confinement to improve its ductility and load bearing capacity

- Increase flexure strength and shear strength of beams and girders

- Wrap the marine structures such as decks, sea walls, pillars

- Tunnels, oil pipes, culvert

- Cracks control before situation becomes even worse

- Modify the positive movement and negative movement

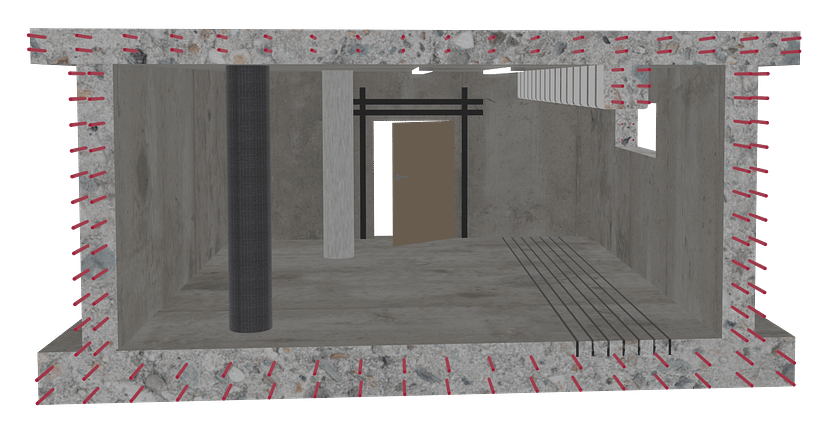

Slab Reinforcement to increase load capacity and flexural strength

Increase ductility and load carrying capacity

near surface mounted with CFRP laminate

beam wrap with CFRP fabric or strip

strengthening of new opening with CFRP strip

Column confinement to increase load capacity and shear strength

Any question or need more information?